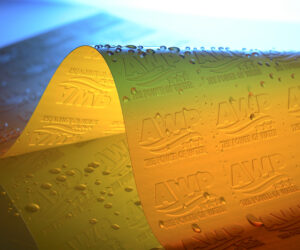

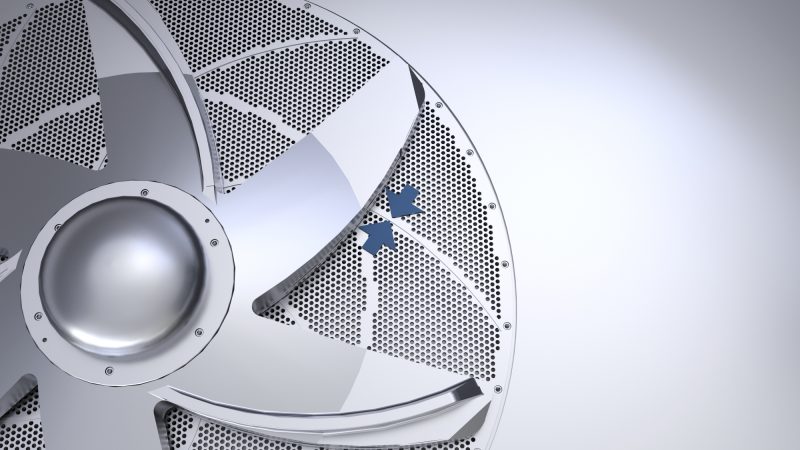

CurvedBar: Voith presents new screen plate with significantly extended service life for recovered paper pulping

Voith introduces a new screen plate design for pulpers used in recovered paper pulping. The CurvedBar screen plate extends service life in Voith’s IntensaPulper IP-R by more than 50 percent and improves the quality of fiber suspension. The results are less maintenance effort and material use, as well as fewer downtimes, leading to a more efficient overall process and lower costs. Chinese paper manufacturer Shanying International Holding Co. LTD., has tested the CurvedBar screen plate on its PM 5 in Maanshan and is now equipping other pulping systems with the innovative solution.

“With the new CurvedBar technology, we substantially reduced downtime

and extended maintenance intervals at the pulper with consistently high

operating quality,” says Wan Tao, Vice President Production at Shanying

International Holding Co. LTD. “We also achieved very positive results from the coarse screening.”

To reduce the high mechanical loads on the screen plate, Voith developed

an innovative curved bar design and optimally matched to the geometries

of pulper, rotor and screen plate. “This results in a much longer service life

compared to conventional screen plates,” explains Oliver Lüdtke, Global

Service and Product Manager at Voith Paper. The lower friction also

reduces energy consumption. “Combined with savings in material and

maintenance, significant cost-saving potential can be realized, and the

customer’s carbon footprint is reduced due to greater sustainability,” says

Lüdtke.

Thanks to the lower shearing forces on the screen plate, far fewer

contaminants are shredded. This improves the quality of the fiber

suspension, reduces the amount of small rejects that need to be

laboriously removed in the downstream process steps, and allows troublefree ragger formation. Furthermore, the risk of bar breakage and

deformation of the screen plate is significantly reduced. The CurvedBar screen plate has proven its effectiveness at Shanying in Maanshan, China, and other locations.

“With the new curved technology and premium W material, we optimized

and reduced the flake content and are maintaining high-efficiency pulping

performance in the long term,” says Song Jie, Manager of the Technical

Department at Shanying International Holding Co. LTD. “The flake content

is about 15 percent, the lifetime of high-efficiency pulping performance is

extended from two months to five months.”

“We still keep very good collaborating relation with Voith for the OCC stock

preparation and paper machine, especially for testing the performance of

the screen plate with CurvedBar and premium W material,” Jie adds. “We

value the excellent and professional support provided by Voith during

installation and commissioning of the screen plates. At all times, Voith was

in close contact with us to continually optimize the equipment. We are very

satisfied with the results and happy to have Voith as a strong partner by

our side.”

Following the successful pilot phase, the company has already awarded

Voith several follow-up orders to successively retrofit other pulpers with the new components. Other customers have also placed repeat orders for the innovative screen plate design following successful testing.

For more information about CurvedBar please visit: http://voith.com/corpen/papermaking/pulping-solutions.html