BritAS at the Fakuma 2021, Hall A6, Booth 6309

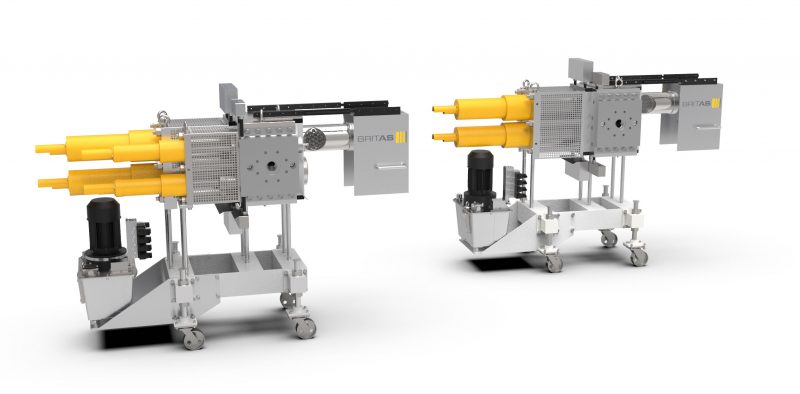

The BritAS team is very happy to show the piston screen changer CMF at its booth in Hall 6 during this years Fakuma! We officially introduce the new ABMF PET-C, the melt filter for contaminated PET.

BritAS piston screen changer presentation at the booth

Ideal for slightly contaminated industrial & production waste. The CMF series includes four lines – discontinuous and continuous versions, which meet all customer requirements. The BritAS piston screen changers are designed for the recycling of plastic waste, which is less contaminated. “We are very happy to present our innovative piston screen changer during the Fakuma. The series includes a continuous version CMF and a discontinuous version DMF – the BritAS piston screen changers are ideal for the recycling of plastic waste with less contamination “, explain Thomas Lehner CSO BritAS Recycling-Anlagen and Heiko Henss, COO BritAS Recycling-Anlagen.

Series with 4 filter types for all requirements

“Mainly, piston screen changers are used in the field of post-industrial, post-production as well as for virgin material. Depending on the required throughputs and different operating modes, customers choose between the discontinuous – mainly with one piston – resp. the continuous – with two pistons – version “, says Lehner.

Basic versions are the CMF as automatic, continuous piston screen changer as well as the DMF as discontinuous piston screen changer in angular and round design. „The DMF-rd has a round housing, which is heated with ceramic heating bands. This more cost-effective filter version is mainly used as pre-filter for coarse contaminations, as pump protection or in case of reduced space (co-extrusion) “, explains Henss.

Due to its angular housing, the DMF-sq is suitable for higher temperatures up to 350° C and higher pressures up to 500 bar and is heated with heating cartridges. Both types can be used for polyolefins, hotmelt adhesives and many technical plastics.

Highlight piston screen changer with backflush function

The CMF-BF, the piston screen changer with backflush function is in a position to clean the filters automatically. In a front-end module, there are two backflush pistons, which allow an automatic backflush procedure. In case of a necessary filter change, first, one of the two backflush pistons is moved into the backflush position. This will interrupt the melt flow of the corresponding filter. A small melt flow of the material, which has already been cleaned will be separated and guided backwards through the filter to be cleaned and guided outwards. Then, this procedure is automatically repeated for the second filter.

For more information, please visit https://www.britas.de/