BLUECARE, new 3d printing powder material for food industry

Developed and produced by FABULOUS for the powder based systems (LS, SLS, HSS, IRS), and based in PA11, BLUECARE material is mass blue and has been certified for Food Contact Application following the “Commission Regulation (EU) No 10/2011 of 14 January 2011 on plastic materials and articles intended to come into contact with food and alcohol.

An applicative material dedicated to Food industry needs

Additive Manufacturing is a production technology growing in every market, changing from prototyping applications to production. The Food Industry (and others) market follows this trend and BLUE CARE comes to answer some of its needs:

- Safety Blue Plastic Parts are used in different industrial areas, as prevention in the food industry, due to their visibility and identification in real time production lines (identification of foreign bodies or fragments of plastics in food by visual or optical blue detection).

- Final machinery parts certified for food contact: parts made of plastic materials and in direct contact with food must meet strict requirements in regard to the materials used, especially when it comes to verifying that the contact is not harmful from a physiological point of view. BLUECARE, through its certifications, meets the requirements of international regulations for parts in contact with food. Also, with BLUE CARE, component cleanliness is easier to evaluate, as spores, mold, food or detergent residue are clearly visible.

The first applications of Bluecare

Partner customers already started producing parts using BLUECARE in January 2021: this is the case of the IDPRINT 3D printing service in France, and the OCEANZ printing service, based in the Netherlands. FDA certification is currently in progress for US market.

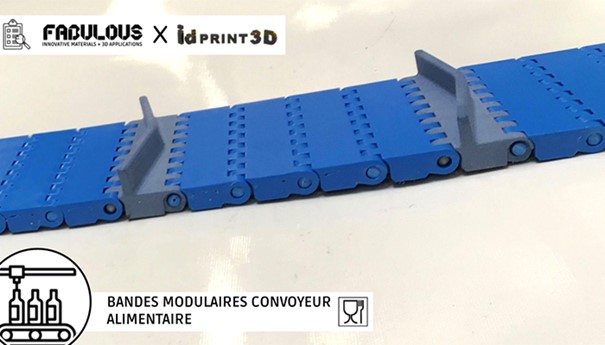

In the case of IDPRINT 3D, BLUECARE powder was used to design 30 cm wide modular food conveyor belts. A success according to Mr. Panchot, manager of IDPRINT 3D, who believes that the material is perfectly adapted to his needs: “BLUECARE is the ideal material for additive manufacturing of parts for food conveyors, avoiding the manufacture of a mold that is too expensive for the number of parts to be made.”

At OceanZ, Fabulous’ material was used to manufacture food nozzles. “This nozzle is in direct contact with the confectionery. The confectionery contains sugar, so we need to avoid an abrasive effect on the nozzle. The BLUECARE material is one of the purest raw materials currently available for production. In addition, the material can be easily cleaned with cleaning agents after the production process. 3D printing with this material therefore opens doors for the food industry,” says Frank Elbersen, sales engineer at the Dutch company.

For more videos about BLUECARE, visit their website blog post.