Looking at Packaging to Limit Logistics Costs

We can’t seem to escape the news surrounding spiralling bills flying at us each and every day. As the noise about the impending financial squeeze gets louder, businesses aren’t hiding the fact that they’re trying to source ways in which they can cut costs. After all, inflation’s hits a 40-year high and we’re teetering on a recession, so something’s got to give. But. And it’s a big but. Within this rather bleak outlook and challenging economic landscape lies opportunity. Genuine opportunity for businesses that genuinely want to explore practices that can innovate their logistical processes. And work to counteract the financial pressures of today, for tomorrow.

Covid-19, the sustainability catalyst

To get to it, we can’t avoid mentioning the global pandemic. When it rains, it pours, hey? Whilst disruption caused by Covid-19 gave many business leaders headaches, namely anyone and everyone involved in some sort of supply chain, it also provided an ideal time to reflect. And we daresay, ‘pause’. By some grace or God – or more realistically, public intervention – Covid-19 catalysed one of the biggest shifts in behaviour. That’s right, we’re referring to sustainability.

Now, for some, it might have been part of the strategy to retain and attract custom during a period of immense pressure and competition in the logistics sector. But, for most, it enabled more. More efficient processes, thanks to applying innovative closed-loop concepts. More effective supply chains, thanks to partnerships with local manufacturers. More environmentally-responsible goods, from using alternative materials during production to ‘greener’ transport choices (through the likes of an electric vehicle).

And, we’re pleased to report that such sustainable awareness wasn’t left in 2021. The aftermath of the pandemic has proven changed business models. In turn, logistics arms must now fully capitalise on those sustainable swaps, shifts, and pledges to help weather this financial storm.

From nightmare to wonderland

Start by taking things back to basics; it’s simple, but effective. Some of the smallest tweaks will have the largest benefits. And it could quite literally be as simple as implementing a process that ensures all pallets are at capacity before transportation, saving:

- Courier costs

- Pallet wrap

- Forklift hire and/or operator costs and time

As well as those carbon emissions that cost the Earth. Combine this with other activities, and you’ll soon find yourself out of a logistics nightmare and into a wonderland.

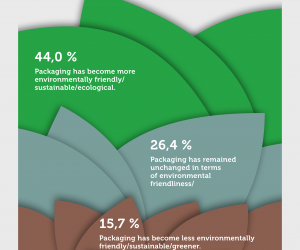

The true cost of packaging

Whilst we’re at it, let’s talk about packaging. Because we’ve all felt the frustration of receiving a parcel that’s quite literally drowning in an excess of materials, from boxes far too large to Sellotape in such abundance that it demands shears to cut through. Why is this still happening, when the potential to make significant cost and environmental savings is so obvious?

Often, it’s convenience. Or belief that bulk buying one-size-fits-all is more cost-effective. Sure, the boxes themselves might be cheaper to acquire in this manner, but what about the:

- Storage space and costs?

- Infills required to protect products not suited to the box size?

- Number and cost of goods that can be transported at once?

Naturally, combining the necessary amount of wrap needed to sufficiently protect a product with the most appropriate box size makes the transported load lighter. Then, loading these boxes optimally for transport – i.e. stacking packages with a little Tetris influence to ensure pallets are full – drives down the energy needed to transport it from here to there. It doesn’t take a genius to see that where a product isn’t packaged in container that’s suitable to its size, weight, or dimensions, there’s more room for error. Cost. Consumer anger. All can be avoided.

Thinking outside the box

Yet it’s not just the products of logistics that can shed the pounds, but operations, too. Take the forklift truck: whether it’s driving straight lines from A to B and back again, or criss-crossing from A to B to C to A (you get the gist) on demand, it’s costing labour, resources, and fuel. Pop a GPS tracker onto your forklift truck to see how far it travels compared to achieved work.

Like taking the pile at the bottom of your stairs up with you, instil a proactive mindset into machinery operators and warehouse floor managers. When a product is dropped off, something else is picked up. And vice-versa. That’s one process where you can try to close the loop.

Every cloud… Current news is complex and rather burdening, but not all business decisions need to be. Granted, we hoped to enjoy a quieter period where things got back to ‘normal’ – whatever that now means – but here we are. There’s no magic wand to wave, but there are opportunities to take advantage of. Refining industry operations will reassert a network that survives, and thrives. To think ‘out the box’ has never held greater meaning.

About the Author:

Louise O’Brien is the Managing Director of Greyhound Box, trusted supplier of corrugated cases. Specialising in consultation, bespoke design, and expert manufacturing of packaging, all solutions are technically crafted and sustainability-centric. Greyhound Box prides itself on continuous operational improvements that increase the efficiencies of its environmentally-responsible processes and products.