Novel technology will help to win the war on plastic waste

In recent years big brands have been making lots of commitments to reduce plastic waste, but in reality, during the COVID-19 pandemic there has been a noticeable rise in waste. Now we are hopefully getting back to thinking more about our environmental impact, how can innovative technology be leveraged to win the war on plastic waste and boost sustainability?

The Ellen MacArthur New Plastics Economy Global Commitment involves some well-known names such as Danone, Nestle and SC Johnson. It aims to unite its signatories behind a common mission to address plastic waste, and notably, it includes companies that represent 20% of all plastic packaging produced globally. Other parties are governments, universities, and industry associations.

At the heart of its Global Commitment is a vision of a circular economy for plastic. Participants commit to three main goals. Firstly, to eliminate all problematic and unnecessary plastic items. Secondly, to innovate to ensure that the plastics we do need are reusable, recyclable, or compostable. Thirdly, to circulate all the plastic items we use to keep them in the economy and out of the environment. Unfortunately, the 2020 progress report showed that a substantial acceleration of progress will be required in the coming years to achieve these targets. The Foundation highlighted the need to:

- Take bold action on packaging types that are not recyclable today — innovating, developing, and executing a credible roadmap to make recycling work

- Establish policies and mechanisms that provide dedicated and stable funding for collection and sorting

- Set a global direction and create an international framework for action, through the UN Environment Assembly, building on the vision for a circular economy for plastics

Recycling challenges

According to new research by recycling and packaging company DS Smith, we are in the middle of a recycling crisis, with many households simply running out of space in their bins and unable to recycle properly. During the pandemic there has been an increase in household waste – with more food packaging, online shopping packaging and takeaway food containers than ever before (much of which is plastic). The report also found there are concerns that the current recycling infrastructure is not equipped to deal with high volumes of recycling.

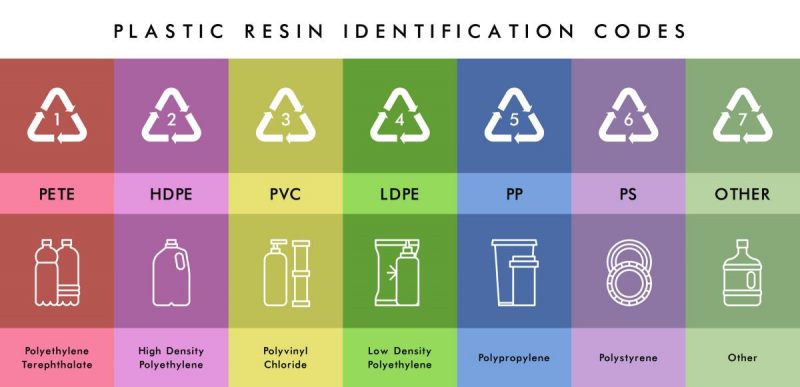

Another challenge is the different plastics that need to be recycled. Plastic is grouped into seven major types:

• Polyethyleneterephthalate – PET

• Hi density polyethylene – HDPE

• Polyvinylchloride – PVC

• Low density polyethylene – LDPE

• Polypropylene – PP

• Polystyrene – PS

• Others – O

The first six of which can all be theoretically recycled, which is why products often will display these codes with a ‘recycle me’ message. Notably, this is usually accompanied by a footnote of ‘check local recycling guidelines’, as acceptance differs by region, generally because not all plastic recycling can be done economically from kerbside collections if access to advanced facilities is not available. This is all very confusing for us, as consumers. Not surprising we don’t always manage to make the right decisions.

If we go back to the commitment of brands to use more recycled materials, in fact recovered PET commands a reasonably high market price, especially if it can be proved to be food grade (facilities have to be licensed to be able to do this). White HDPE – which is used for household products, personal care, milk bottles etc – also has a good recovered price. The challenge is to be able to sort these materials out of the general waste coming from our bins, not just from paper and glass, but from the other types of plastic.

Can technology help?

Technology can help increase the recovery of valuable resources (packaging) and improve recycling processes. RFID (Radio Frequency IDentification) could be used in both these cases. This is more reliable than barcodes. It can now be leveraged with new ultra-low-cost flexible electronics to uniquely identify packaging, with a low-cost RFID inlay (tag) being embedded into each package with a unique identifier (UID) enabling item-level tracking and interactivity. The UID can link to more detailed information, allowing people to access localised recycling information with a simple tap of their smartphone – making it easier for them to do the right thing. Going further – a next generation smart recycling bin system (at-home and on-the-go) could complement Deposit Return Schemes, incentivising consumers by giving digital rewards for how much is collected. Plus, crucially, this novel technology could be used at material recovery and municipal facilities to ensure more effective sorting of plastics and packaging waste.

This technology could also be a solution to an issue recently publicised in the news – a Greenpeace report that claims UK plastic waste is being exported to Turkey and then illegally dumped and burned. If everyday products were embedded with low-cost RFID and flexible electronics that allows digital item-level traceability, this would help prevent illegal dumping of plastics.

Doing the right thing

The great majority of us want to do the right thing and to play our part in addressing the global challenge of plastic waste. The best way to increase plastics recycling and re-use is to reduce the barriers for consumers and reduce friction within the whole supply chain. Using innovative technology like low-cost RFID and flexible electronics could help us to do that.

Alastair Hanlon – Chief Commercial Officer